Quality Control

Rigorous Quality Control for High-Performance Microphones and Headphones

LED Color Tests, as a professional microphones and headphones factory, we have online testing equipment to control the quality for each materials. this is a machine for testing the color of LED light shows on correct color or not.

At YOGADA, we have over 35 years of expertise as a professional OEM & ODM factory, specializing in delivering high-quality microphones and headphones. Our stringent quality control processes ensure that our products meet and exceed industry standards, providing you with the assurance you need for your business.

Comprehensive Quality Management System

Our ISO 9001-certified quality management system underscores our commitment to consistent quality. Key components include:- Incoming Material Inspection: Every batch of raw materials and components is thoroughly inspected using our XRF Spectrometer to ensure compliance with strict quality and regulatory requirements.</p>

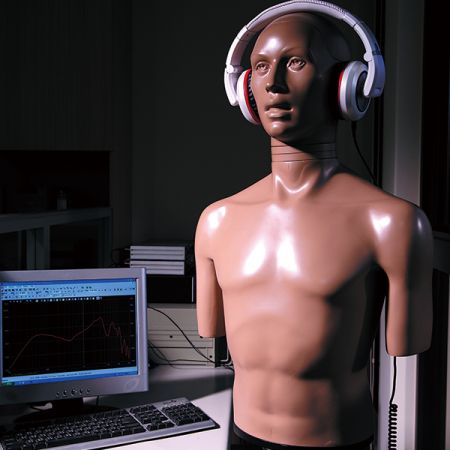

- In-Process Quality Control: Regular checks and monitoring are performed during manufacturing to identify and rectify issues in real-time, ensuring that our high-performance microphones and headphones maintain consistent quality.</p>

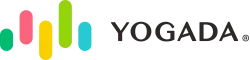

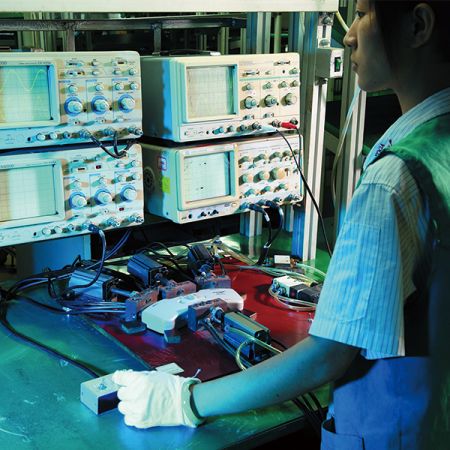

- End-of-Line Testing: Each finished product undergoes rigorous testing, including acoustic performance checks with the B & K Audio Analyzer, and comprehensive electro-acoustic testing with the CLIO IEA Electro-Acoustic System.</p>

Professional Testing and Analysis Equipment

YOGADA employs professional testing equipment to guarantee the quality and reliability of our high-quality microphones and headphones:•. Anechoic Chamber Room: Provides a controlled environment for accurate acoustic testing, ensuring our products meet stringent performance standards.

•. XRF Spectrometer: Allows precise material composition analysis, ensuring compliance with material specifications and regulatory requirements.

•. Reliability Test: Extensive reliability testing to ensure our products can withstand various environmental conditions and usage scenarios, providing long-lasting performance.

•. RoHS Test: Ensures all products are free from hazardous substances, meeting environmental and safety standards.

•. Temperature and Humidity Machine: Simulates various environmental conditions, testing durability and performance under extreme temperatures and humidity levels.

Continuous Improvement and Customer Feedback

We are committed to continuous improvement through:

•. Regular Audits and Reviews: Conducting internal and external audits to assess the effectiveness of our quality control processes.

•. Customer Feedback Integration: WIth after service and incorporating feedback from our clients to refine our products and services.

Commitment to Quality Assurance

YOGADA’s commitment to quality assurance extends beyond production, with comprehensive after-sales support to address any issues promptly. Our dedicated support team is available to assist with technical inquiries and resolve any potential concerns.

Partner with YOGADA for Your OEM & ODM Needs

When you choose YOGADA as your professional OEM & ODM factory, you benefit from our: • High-Performance Microphones and Headphones: Guaranteed quality and performance through rigorous testing and advanced technology. • Professional OEM & ODM Services: Tailored solutions to meet your specific business requirements. • High-Quality Standards: Consistently high-quality products certified by ISO, CE, and RoHS standards. • Timely Delivery and Reliable Supply Chain: Ensuring your products arrive on time, every time.Partner with YOGADA for your high-performance microphones and headphones needs, and experience the benefits of working with a leader in the industry. Contact us today to learn more about our advanced R&D capabilities and how we can support your product development goals.Complete Quality Assurance System

- Material Testing Standard: MID-STD 105E, Level 2

- Hazardous Substances 100% Analyzed by XRF Spectrometer.

- Continuous Assurance Tests: Reliability Test, Damage Test, Life Cycle Test, and Functional Tests.

Requirements on RoHS 3 / RoHS 10 Compliance

- Lead 0.1 % (1000 ppm)

- Mercury 0.1 % (1000 ppm)

- Cadmium 0.01% (100 ppm)

- Hexavalent chromium 0.1% (1000 ppm)

- Polybrominated biphenyls (PBB) 0.1% (1000 ppm)

- Polybrominated diphenyl ethers (PBDE) 0.1% (1000 ppm)

- Bis(2-ethylhexyl) phthalate (DEHP) 0.1% (1000 ppm)

- Butyl benzyl phthalate (BBP) 0.1% (1000 ppm)

- Dibutyl phthalate (DBP) 0.1% (1000 ppm)

- Diisobutyl phthalate (DIBP) 0.1% (1000 ppm)

相簿集

- Cable flexibility test machine for microphones and headphones, our products are finish reliability Test, drop test..etc before the model to be MP.

- Switch Life Tester, as a professional audio product factory, even a tiny element in the product will do fully test to ensures the quality.

- X-Ray Chemical elements Analyzer - SEA1000A Ⅱ XRF spectrometer, to analyze if the chemical elements in each materials meets RoHS and CE rules.

- Artificial Ear (Ear Simulator) for testing headphones.

- Frequency Curve Check in our QA dept to ensure each headphone or microphone will be in standard.

- Voice Coil Check, especially dynamic capsules for audio microphones are made in our factory, we will do fully inspection before assembling.

- CLIO IEA EA-2 Electro-Acoustic Integrated System.